Quality

Microsoft Gold Partner

Every year, Microsoft honors only few companies with Gold Partner status for certain competencies.

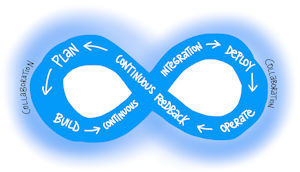

DevOps stands for a new approach in the collaboration of previously separate departments. Development (software development) and operations (IT operations) pull together to increase software quality and availability, thereby increasing customer satisfaction.

This process improvement approach enables continuous delivery of applications and solutions to customers. Through automation, the DevOps method enables faster cycles to meet new business demands. Development and operation come closer together and coordinate their work for the benefit of the customer. Investments in practices that increase throughput and stability improve IT performance.

WENZEL Metromec has been successfully in developing software solutions for coordinate metrology for more than 40 years. For several years, the leading product

WM | Quartis has been developed according to the principles and practices of Continuous Integration / Continuous Delivery. The frequent, automated build and testing of the product promotes the efficient implementation of customer requirements while ensuring the high-quality standards of WM | Quartis.

Based on the practical experience at WENZEL Metromec, it is a logical step to also document the existing competence formally with a successful certification as a Microsoft Gold Partner.

DevOps advantages at a glance

- Acceleration of the software development by increasing the level of automation, efficiency and agility

- Lower error rate for new releases, better product quality and more stable releases

- Market-oriented products

- Faster resolution of problems

- Improved collaboration and transparency

- Long-term motivated and loyal employees

WQP – WENZEL Qualification Program

WENZEL has implemented a global qualification program in order to meet the growing customer expectations for the After Sales Service and Application Center.

WENZEL has implemented a global qualification program in order to meet the growing customer expectations for the After Sales Service and Application Center.

With the WQP, WENZEL ensures a globally coherent service at the highest level. The program ensures customers that the work and corrections on their measuring machines are performed by well trained and qualified personnel.

The stringent audit process certifies WENZEL service partners for the WQP for a period of 36 months.

WQP certificate bridge machines >>

WQP certificate application center >>

clean code developer

Measuring software products from WENZEL Metromec AG are know for their reliability. The proverbial Swiss quality creates confidence. And confidence in results, especially in measurement results, is an absolute requirement for our customers in the automotive, aircraft, aerospace, medical and engineering industries.

Measuring software products from WENZEL Metromec AG are know for their reliability. The proverbial Swiss quality creates confidence. And confidence in results, especially in measurement results, is an absolute requirement for our customers in the automotive, aircraft, aerospace, medical and engineering industries.

Professional, high quality, innovative and reliable measurement software does not come by itself, it requires great effort, in addition to the visible and tangible outer quality of the Metrosoft products also ensure a high quality of inner code.

WENZEL Metromec AG continually improves its development process. Teams and individuals reflect workflows, methodology, tools and different ways of cooperation. Professionalism requires a self-critical posture. Proven approaches and practices are enhanced, potential for improvement identified and courageously considered.

This way,WENZEL Metromec ensures and maintains a high grade of stability, scalability, efficiency and sustainable succest. WENZEL Metromec AG orientates itself for the development of measuring software according to the values, principles and practices of the Clean Code Developer Initiative (CCD-Initiative).

Quality management system in conformance with ISO 9001:2000

WENZEL Metromec AG strives for high quality and understands by that a high correspondence of its products and services with customer requirements.

With a process-oriented quality management system, which rests on a total-company Q-culture and the sensitized Q-consciousness of all employees, we guarantee that our demanding Q-goals are reached.

Our quality management system fulfils the internationally recognized requirements laid down in quality management standard SN EN ISO 9001 : 2000.