WENZEL presented numerous innovations at Control

May 28th, 2019 - At this year's Control, WENZEL presented a multitude of solutions in the fields of coordinate measuring technology, computer tomography and optical high-speed scanning.

Coordinate measuring technology for the inspection room and production

Coordinate measuring technology for the inspection room and production

For more than 50 years WENZEL has been offering high-precision and innovative measurement solutions for quality assurance in all industries. At this year's Control in Hall 5, Stand 5101, the Wiesthaler company will present new solutions for current trends such as Inline-Metrology, Closed Loop, Optical Acquisition and Big Data Analytics from its wide range of products in the fields of coordinate measuring technology, computed tomography and optical high-speed scanning. The focus will be on the shop floor and on automation. On one side of the more than 350 sqm stand WENZEL presents all the products which can be used directly in the production and on the other side, all the solutions which were specifically developed for the inspection room are to be found.

The measuring solution provider will of course show some coordinate measuring machines (CMMs) from its proven R and LH series. The new line sensor WM | LS 70 is presented to the public for the first time on a horizontal arm measuring machine of the R series.

The measuring solution provider will of course show some coordinate measuring machines (CMMs) from its proven R and LH series. The new line sensor WM | LS 70 is presented to the public for the first time on a horizontal arm measuring machine of the R series.  Together with the new partner Kreon, it was adapted to address the needs of customers and is integrated into the powerful WM | Quartis measuring software. The partnership also includes the WM | MMA portable 7-axis measuring arm in the WENZEL product portfolio. This enables location-independent and flexible measurement in the production and quality assurance process. The combination of the measuring arm with the high-resolution WM | LS line scanners, which capture every detail contact-free, is a good complement to the classic CMMs.

Together with the new partner Kreon, it was adapted to address the needs of customers and is integrated into the powerful WM | Quartis measuring software. The partnership also includes the WM | MMA portable 7-axis measuring arm in the WENZEL product portfolio. This enables location-independent and flexible measurement in the production and quality assurance process. The combination of the measuring arm with the high-resolution WM | LS line scanners, which capture every detail contact-free, is a good complement to the classic CMMs.

As a consequence of industry 4.0, the reduction of batch sizes and a strongly growing interest in 100% measurement requires more and more automated solutions in the shop floor environment. The multiple award-winning SF 87 outperforms many machines in this segment due to its very large measuring volume, the absence of air bearings and thus fewer connections and low consumption. WENZEL shows the SF 87 twice, once for probing and once enclosed in a very efficient automation solution, together with the partner Zimmer+Kreim.

As a consequence of industry 4.0, the reduction of batch sizes and a strongly growing interest in 100% measurement requires more and more automated solutions in the shop floor environment. The multiple award-winning SF 87 outperforms many machines in this segment due to its very large measuring volume, the absence of air bearings and thus fewer connections and low consumption. WENZEL shows the SF 87 twice, once for probing and once enclosed in a very efficient automation solution, together with the partner Zimmer+Kreim.

In the course of a closer cooperation with Renishaw, the Equator gaging device can now be controlled directly via the well-known WENZEL software WM | Quartis for programming and evaluation. The Equator gage is now also part of the WENZEL portfolio.

In the course of a closer cooperation with Renishaw, the Equator gaging device can now be controlled directly via the well-known WENZEL software WM | Quartis for programming and evaluation. The Equator gage is now also part of the WENZEL portfolio.  At the same time WENZEL launches the SF 55 a further compact bridge measuring machine for employment directly in production. Like the larger SF 87, this machine concept offers a very good price-performance ratio in a small footprint. High traversing speeds and accelerations ensure a high measuring throughput. As an "Equator-Calibrator", the SF 55 is the ideal measuring machine when packaged with the Equator, which carries out comparative test measurements on the basis of a master data set.

At the same time WENZEL launches the SF 55 a further compact bridge measuring machine for employment directly in production. Like the larger SF 87, this machine concept offers a very good price-performance ratio in a small footprint. High traversing speeds and accelerations ensure a high measuring throughput. As an "Equator-Calibrator", the SF 55 is the ideal measuring machine when packaged with the Equator, which carries out comparative test measurements on the basis of a master data set.

WENZEL is also showing the very successful combination of the REVO 5-axis measuring head from Renishaw on an LH bridge measuring device. In the new release of the WM | Quartis software, further improvements have been implemented to increase accuracy and user friendliness. For example, the new sweep scan measurement enables the efficient acquisition of surfaces with manual distribution on the CAD model.

On another LH CMM, WENZEL has integrated a turntable and provides insights into the latest solution for the measurement of gears on a conventional coordinate measuring machine. The WM | Gear solution is based on WM | Quartis and generates standardized GDE files which can then be evaluated with the WM | Gear Analyzer. WM | Gear is a completely new software package for data acquisition and measurement of involute spur gears. Together with the WM | Gear Analyzer for evaluation and presentation of the measurement results, a complete package for quality determination of involute gears is available.

On another LH CMM, WENZEL has integrated a turntable and provides insights into the latest solution for the measurement of gears on a conventional coordinate measuring machine. The WM | Gear solution is based on WM | Quartis and generates standardized GDE files which can then be evaluated with the WM | Gear Analyzer. WM | Gear is a completely new software package for data acquisition and measurement of involute spur gears. Together with the WM | Gear Analyzer for evaluation and presentation of the measurement results, a complete package for quality determination of involute gears is available.

In addition, there are improvements in the area of optical high-speed scanning. The hybrid sensor (optical and tactile) presented last year as a prototype is ready for series production. With the new version of WM | Quartis it is also possible to configure the CORE measuring device and to operate it with its tactile sensors as well as with optical double-eye sensors. With the WM | Blade Analyzer WENZEL introduces a new tool for the evaluation of turbine blade measurements. The new benchmark in blade measurement – for all turbine manufacturers in power engineering as well as in the aerospace industry.

In addition, there are improvements in the area of optical high-speed scanning. The hybrid sensor (optical and tactile) presented last year as a prototype is ready for series production. With the new version of WM | Quartis it is also possible to configure the CORE measuring device and to operate it with its tactile sensors as well as with optical double-eye sensors. With the WM | Blade Analyzer WENZEL introduces a new tool for the evaluation of turbine blade measurements. The new benchmark in blade measurement – for all turbine manufacturers in power engineering as well as in the aerospace industry.

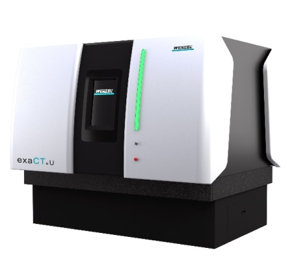

The computer tomography solutions will also be demonstrated at the booth. This time the desktop CT exaCT S and the exaCT M workstation. The universal exaCT U can be seen as a dummy on site. The technology of the WENZEL computer tomographs is adapted for applications in various industries, where the internal and external structures of components must be detected completely and quickly. The CT market has developed very positively for WENZEL in the last 12 months.

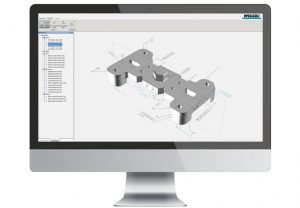

As already stated, there are many improvements for the customers for all measurement solutions, especially on the software side. The convergence of different software applications saves license costs and users can easily perform different tasks with a single software. This reduces the necessary trainings and makes operation easier. In addition, WENZEL has recognized the trend that measurement programs no longer have to be generated individually but can be automatically generated based on the information in the CAD model. The first "proof of concept" of the software WM | Generator has successfully been started and the first approaches can already be shown at the Control 2019, also with the ulterior motive to receive valuable feedback from specialists with practical experience.

As already stated, there are many improvements for the customers for all measurement solutions, especially on the software side. The convergence of different software applications saves license costs and users can easily perform different tasks with a single software. This reduces the necessary trainings and makes operation easier. In addition, WENZEL has recognized the trend that measurement programs no longer have to be generated individually but can be automatically generated based on the information in the CAD model. The first "proof of concept" of the software WM | Generator has successfully been started and the first approaches can already be shown at the Control 2019, also with the ulterior motive to receive valuable feedback from specialists with practical experience.