WENZEL CMM Accelerates Measurements of Contract Manufactured Parts

17.11.15 - To meet the high quality requirements, the USD Formteiltechnik GmbH relies on coordinate metrology from the WENZEL Group. In order to measure faster and more accurately a WENZEL LH 65 CMM with Metrosoft QUARTIS was put into operation.

The USD Formteiltechnik GmbH delivers around 6,000 different contract parts using the investment casting, sand casting, die casting, sintering, MIM, drop forging, pressing and turning manufacturing processes. There are no limits to the diversity.

The USD Formteiltechnik GmbH delivers around 6,000 different contract parts using the investment casting, sand casting, die casting, sintering, MIM, drop forging, pressing and turning manufacturing processes. There are no limits to the diversity.

The applications are very different. Sectors served are for example automotive technology, machinery and engineering, agricultural devices, food technology, medical engineering, precision engineering or valves and pumps.

Universal and Flexible Measurement

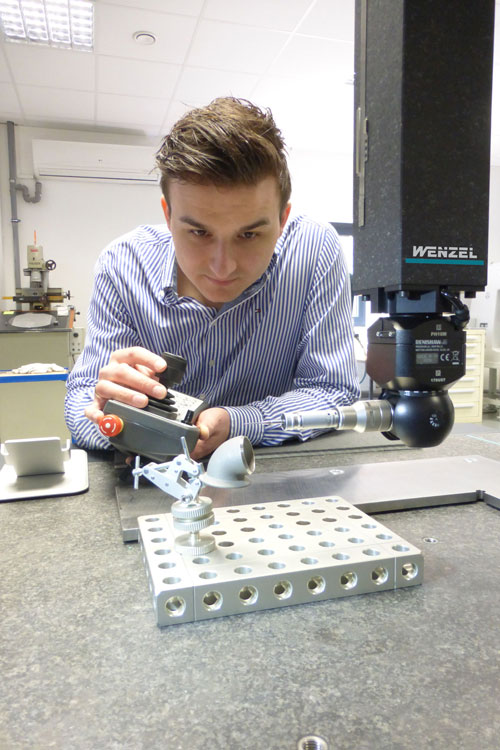

The LH 65 from WENZEL, a German manufacturer of metrology equipment, is a universal, flexible coordinate measuring machine for different applications matching the varied requirements of USD. For USD it is important to measure the length, shape and position of the parts high precisely, quickly and reliably. The required measuring accuracy depends on the component size and is usually less than 10 µm. This is no problem for the coordinate measuring machine from WENZEL. Equipped with the PH10M motorized indexing head and the compact TP200 probe system from Renishaw, the CMM has an accuracy of 2.1 + L / 300 µm..

The LH 65 from WENZEL, a German manufacturer of metrology equipment, is a universal, flexible coordinate measuring machine for different applications matching the varied requirements of USD. For USD it is important to measure the length, shape and position of the parts high precisely, quickly and reliably. The required measuring accuracy depends on the component size and is usually less than 10 µm. This is no problem for the coordinate measuring machine from WENZEL. Equipped with the PH10M motorized indexing head and the compact TP200 probe system from Renishaw, the CMM has an accuracy of 2.1 + L / 300 µm..

The high mechanical accuracy and high machine run times are secured through the use of high-quality components. Identical thermal behavior of granite in all axes ensures the high accuracy of the LH Series. Its thermal behavior and the minimal residual stress make granite the number one raw material for metrology structures. The Metrosoft QUARTIS software used is the latest generation of measuring software with a goal-oriented architecture. The comprehensive and intuitive software package is widely used in the market.

Time-Saving Measurement Against 3D Data

The new measurement solution meets the constantly changing requirements for quality of various components. USD gets meaningful measurement results quickly and easily even for complex workpieces. For example, the company was faced with the challenge of producing a component for exhaust gas recirculation for a German car manufacturer and to ensure its high quality.

Particularly significant was determining the profile shape tolerance. The new WENZEL coordinate measuring machine verified with that the component meets the aerodynamic specifications. Also it was very important to the customer to avoid the influence of the operator on measurement results as good as possible and to automate measurement procedures as far as possible. Measurements against 3D data were performed time-saving and the production orders could be handled on time.

Automation of Measurement Procedures and Consistent Service Concept

The investment has paid off for USD. But before the measuring machine was installed in the tempered measuring room which is designed according to VDI / VDE 2627, grade 3, there was a strict selection process. USD compared several measuring solutions from different manufacturers. "Important for us was the ability to automate the measurement processes while reducing the operator influence on the measurement results," explains Christian Kosak, General Manager of USD. Further crucial criteria were the accuracy, the measurement throughput, powerful and easy-to-use measurement software and the support of existing CAD and CAQ systems.

The investment has paid off for USD. But before the measuring machine was installed in the tempered measuring room which is designed according to VDI / VDE 2627, grade 3, there was a strict selection process. USD compared several measuring solutions from different manufacturers. "Important for us was the ability to automate the measurement processes while reducing the operator influence on the measurement results," explains Christian Kosak, General Manager of USD. Further crucial criteria were the accuracy, the measurement throughput, powerful and easy-to-use measurement software and the support of existing CAD and CAQ systems.

"Last but not least, the convenience and operability of the machine and the service concept were significant aspects to our final decision,” adds Michael Seibel, Head of Quality Assurance. In addition to traditional service activities such as maintenance, repair and spare parts management, WENZEL offers further services such as the WENZEL Online Service as well as training and measuring services. An increasingly popular offering are service agreements like maintenance and software maintenance contracts, as well as software updates and upgrades.