Improvements Metrosoft QUARTIS R14

At a glance

Metrosoft QUARTIS R14 offers a wide range of improvements for all users and significantly contributes to optimize daily metrology work.

Metrosoft QUARTIS R14 offers an advantageous and unified operation for the evaluation of further standardized inspection features. Results are already displayed in the graphics via the live preview during the evaluation. The tolerance graphics of the position features shows the form, position and extension of the tolerance zone together with the tolerated element directly in the context of the CAD model.

Metrosoft QUARTIS R14 offers users that measure sheet and plastic parts decisive advantages when displaying the results on graphical measurement reports. Connection lines between features are drawn in a selectable mode. Elements without a data label can be hidden.

Metrosoft QUARTIS R14 exports the measurement results for the data exchange into the BMWIpp format. As a result of the text based data format the exported data can be processed according to the individual needs.

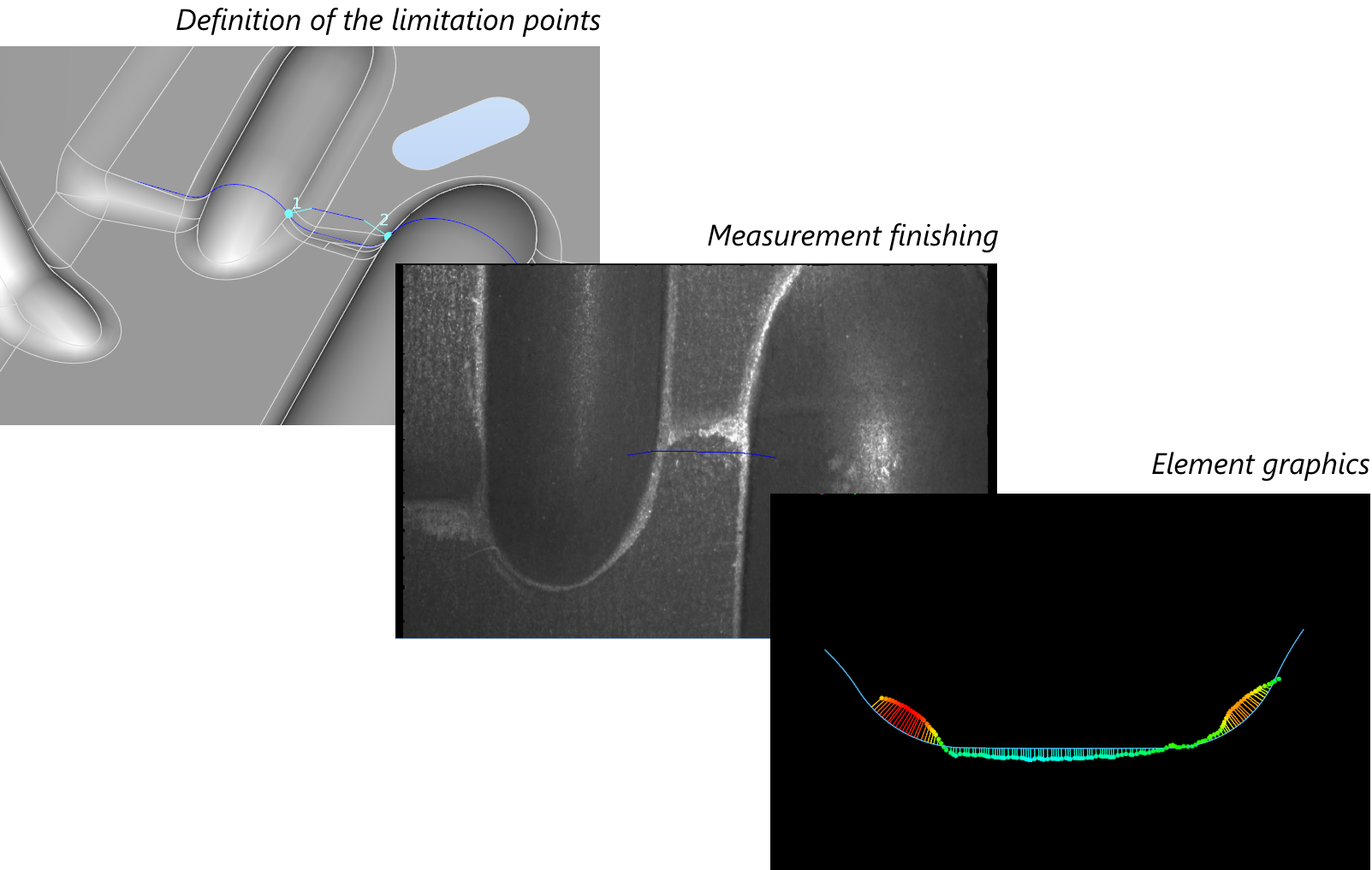

Metrosoft QUARTIS R14 optimizes the measurements with the optical PHOENIX II 3D sensor. So curves can now also be measured optically.

Metrosoft QUARTIS R14 contains new interfaces for machines and integrates further peripheral machines. The Hexagon RDS interface allows the operation with portable measuring arms. With the Renishaw REVO RSP3-6 scanning sensor extensions up to 800 mm can be used.

Metrosoft QUARTIS R14 offers, besides the updated CAD interfaces, many additional improvements and extensions. You find more information on the following pages.

Some improvements are not includes in the standard product Metrosoft QUARTIS R14 an require additional, chargeable modules. These are described in the document "Products and Modules Metrosoft QUARTIS R14".

Standardized feature evaluation

Advantageous, unified operation within the ribbon with live preview

Eight additional features are now evaluated via the ribbon, resulting in significant advantages when measuring, programming and editing.

When evaluating distances and position features a live preview is displayed in the graphics. This illustrates if the evaluation corresponds to the tolerance indications on the drawing.

The tolerance graphics of the position features shows the form, position and dimension of the tolerance zone together with the tolerated element directly in the context of the CAD model.

Parallelism and angularity of planes taking into account the form deviation

For the features "parallelism" and "angularity" the form deviation can now be considered as well when the reference is an axis (cylinder, line etc.).

Highlights

Descriptive measurement report and data transfer

Display connection lines between elements

For feature labels and data labels with two tolerated elements now the connection line to both elements is shown. For different applications the graphical representation of the connection line can be specified.

Hide elements without data labels

You measure many points in comparison to CAD and would like to create clear reports. In the graphics view of the report now the option "Hide elements without data label" is available.

Export measurement data in BMWIipp format

For data transfer you would like to output measurement results in BMWIpp (BMW Inspection plan and protocol) format. QUARTIS has the specific export function. The data of the selected elements is written to a CVS file. As a result of the text based data format the exported data can be processed accordingly to the individual needs.

Highlights

PHOENIX sensor and peripheral devices

WENZEL PHOENIX sensor measures curves

The optical PHOENIX II 3D sensor now also records curve elements in one operation. For optically recorded curves, all construction functions and evaluation functions are available.

More improvements, like the automatically measuring window (ROI) and optimized calculation algorithms, increase the accuracy and enhance the usability.

Renishaw ACR1 via RS-232 interface

The active CAR1 probe, controlled via RS-232 interface, allows among other things stylus change with reduced speed.

Control measuring arm via RDS interface

For operating portable measuring arms the Hexagon RDS interface is available. The following arms are amongst others supported: Romer Absolut, Cimcore C7, Tesa Multigage.

Use Renishaw REVO RSP3-6 scanning sensor

You measure large assembly parts and need long scanning sensor. With the Renishaw REVO RSP3-6 scanning sensor extensions up to 800 mm can be used.

Renishaw REVO SFP1 roughness sensor

You mesure roughness with the REVO SFP1 sensor and would like to use the existing evaluation software. For this, you can transfer the roughness raw data in x3p format. The adjustable alignment tolerance of the C axis avoids unnecessary rotations and thus optimizes the use.

Highlights |

|

Additional improvements

The following useful functions have been addes in Metrosoft QUARTIS R14:

|

|

|

|